In a significant advancement toward sustainable energy solutions, Indian researchers have developed a novel, cost-effective, metal-free catalyst that can efficiently produce hydrogen (H₂) fuel by harvesting mechanical energy. This innovation represents a major breakthrough in green hydrogen technology and offers a promising path toward cleaner alternatives to fossil fuels.

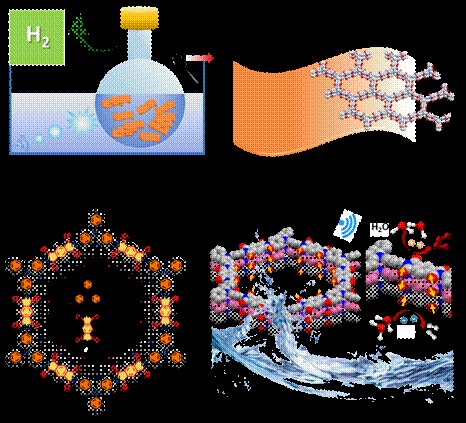

The research, led by Professor Tapas K. Maji of the Chemistry and Physics of Materials Unit at the Jawaharlal Nehru Centre for Advanced Scientific Research (JNCASR), Bengaluru, introduces a donor-acceptor based covalent organic framework (COF) that acts as a highly efficient piezocatalyst for water splitting—a method that separates hydrogen from water molecules.

Unlike traditional catalysts that rely heavily on metal-based ferroelectric materials, the new COF system is entirely organic and metal-free. It is composed of tris(4-aminophenyl)amine (TAPA) as the donor molecule and pyromellitic dianhydride (PDA) as the acceptor. These materials form imide linkages that give rise to a unique structural phenomenon known as ferrielectric (FiE) ordering.

“This breakthrough challenges the traditional reliance on heavy or transition metal-based catalysts, offering a new direction in the development of scalable, sustainable hydrogen production systems,” said Prof. Maji.

What sets this material apart is its sponge-like porous architecture that facilitates efficient water diffusion and access to charge carriers. The FiE ordering in the COF creates intense local electric fields at the pore surfaces, enabling high-density charge accumulation and, in turn, high yields of hydrogen fuel.

Prof. Umesh V. Waghmare, a collaborator from JNCASR, contributed theoretical insights showing that the COF’s electronic structure features coupled energy bands and dipolar ordering. This causes lattice instability, enabling dynamic interaction with mechanical pressure. When stimulated mechanically, the material generates electron-hole pairs, catalyzing the water-splitting reaction with exceptional efficiency.

The study, published in Advanced Functional Materials, involved a multidisciplinary team, including researchers Ms. Adrija Ghosh, Ms. Surabhi Menon, Dr. Sandip Biswas, and Dr. Anupam Dey from JNCASR. Additional contributions came from Dr. Supriya Sahoo and Prof. Ramamoorthy Boomishankar from the Indian Institute of Science Education and Research (IISER), Pune, and Prof. Jan K. Zaręba from Wrocław University of Science and Technology, Poland.

This innovative catalyst not only reduces dependency on expensive and environmentally harmful metals but also offers a viable method to harness ambient mechanical energy—such as vibrations or pressure—for clean energy generation. The development aligns with India’s National Green Hydrogen Mission, aimed at promoting large-scale green hydrogen production and positioning the country as a global leader in this emerging sector.

With global urgency to transition to renewable energy sources, the success of this metal-free piezocatalyst marks a critical step in enabling efficient, clean, and sustainable hydrogen fuel technology.